Why Consistency Matters in Bioactive Fertilizer Ingredients

As agriculture moves away from traditional, high-input chemical practices, bioactive fertilizer ingredients have become central to more sustainable and efficient crop production systems. Excessive use of conventional fertilizers has contributed to soil degradation, nutrient runoff, environmental pollution, and reduced crop resilience to stress. These challenges highlight the need for a more advanced nutrient management strategy—one that prioritizes ingredient consistency, bioavailability, and biological functionality.

Modern peptide amino acid–based bioactive fertilizers represent this shift. By incorporating highly active small-molecule compounds, these products enhance nutrient uptake, support plant metabolism, and improve crop quality through mechanisms supported by agronomic and biochemical research.

Understanding Bioactive Fertilizer Ingredients

Bioactive fertilizers are formulated to do more than simply supply nutrients. They are designed to interact with plant and soil biological systems, improving nutrient efficiency and overall crop performance.

Cellular Activation and Plant Metabolism

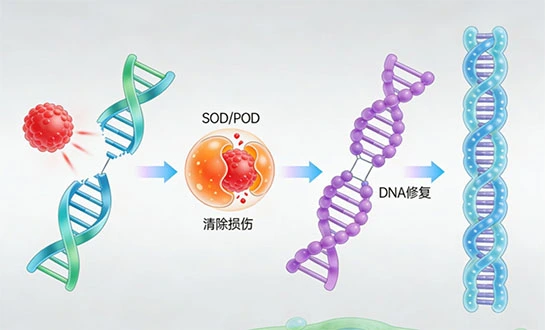

Peptide amino acids act as signaling molecules that activate plant cellular pathways. These pathways regulate cell division, enzyme activity, and metabolic efficiency. Enhanced cellular activity leads to stronger root systems and expanded leaf area, increasing the plant’s capacity to absorb water and nutrients.

Experimental studies, including research on maize, have shown that foliar application of polypeptide amino acids can significantly increase stomatal conductance. This effect is associated with improved cell wall flexibility and membrane permeability, supporting more efficient gas exchange and photosynthesis.

Nutrient Chelation and Bioavailability Enhancement

One of the most important functional advantages of peptide-based bioactive fertilizers is their chelation capacity.

Chelation Mechanisms of Polypeptide Amino Acids

Polypeptide amino acids contain multiple carboxyl and functional groups capable of forming stable chelates with metal ions in the soil. This chemical interaction reduces nutrient fixation and improves the solubility of essential elements such as phosphorus, potassium, calcium, magnesium, iron, and zinc.

As a result, nutrients remain available for plant uptake even under suboptimal soil conditions, including high pH, salinity, or compacted soils.

Improved Nutrient Use Efficiency

By enhancing nutrient mobility and availability, bioactive fertilizer formulations help plants achieve higher nutrient use efficiency. This reduces overall fertilizer demand, minimizes nutrient losses, and supports more sustainable fertilization strategies without compromising yield or quality.

Factors Affecting Consistency in Bioactive Fertilizers

While bioactive fertilizers offer clear agronomic benefits, maintaining ingredient consistency remains a critical challenge for manufacturers and procurement teams.

Raw Material Variability

Natural raw materials inherently vary in protein content, amino acid composition, and microbial activity. These variations can directly affect the final bioactivity of the fertilizer.

High-quality protein sources, such as premium yeast-derived proteins with protein content exceeding 60%, provide greater consistency compared to conventional organic materials. Their controlled production reduces batch-to-batch variability and supports standardized formulation outcomes.

Manufacturing Process Control

Production conditions—including temperature, pH, enzyme selection, and hydrolysis time—significantly influence peptide molecular weight distribution and bioactivity. Advanced enzymatic hydrolysis technologies, such as full-spectrum directed systems developed over decades, enable precise control of these parameters.

These systems ensure that the majority of peptides remain below 1000 Daltons, a molecular size associated with optimal absorption, stability, and biological effectiveness.

Storage and Handling Conditions

Post-production handling can also impact ingredient stability. Exposure to extreme temperatures, moisture, or prolonged storage may degrade sensitive peptide structures.

Bioactive fertilizers engineered for thermal stability maintain performance across a wider temperature range, allowing safer storage, transport, and compatibility with other agrochemicals during tank mixing.

Ensuring Ingredient Consistency Through Best Practices

Consistency in bioactive fertilizer production depends on strict quality management systems and standardized operational procedures.

Advanced Manufacturing Technologies

Modern production facilities utilize controlled enzymatic hydrolysis and real-time monitoring to regulate molecular weight profiles. In high-quality formulations, over 80% of peptides meet the targeted small-molecule specification, ensuring rapid absorption and consistent biological activity.

Quality Assurance and Testing Protocols

Effective quality assurance begins with raw material screening and continues throughout production. Manufacturers routinely analyze protein content, amino acid composition, and molecular weight distribution at multiple stages.

These protocols ensure that each batch delivers predictable performance and meets predefined bioactivity standards.

Storage and Distribution Standards

Proper storage conditions—temperature control, humidity management, and protective packaging—are essential to preserve ingredient integrity throughout the supply chain. Stability-engineered bioactive fertilizers retain their functional properties during transport and long-term storage, supporting reliable large-scale distribution.

Comparing Bioactive Fertilizers with Other Fertilizer Types

From a consistency and performance perspective, bioactive fertilizers offer advantages over both chemical and conventional organic fertilizers.

Limitations of Chemical Fertilizers

Chemical fertilizers provide uniform nutrient content but lack biological functionality. They do not contribute to soil microbial balance and may cause long-term issues such as soil acidification, nutrient leaching, and environmental contamination.

Variability in Traditional Organic Fertilizers

Organic fertilizers depend on natural decomposition processes, leading to wide variation in nutrient release rates and bioactivity. Differences in raw materials, composting methods, and environmental conditions make performance less predictable.

Advantages of Bioactive Fertilizer Systems

Bioactive fertilizers combine controlled production consistency with biological benefits. Their stable ingredient profiles support soil health, enhance crop resilience, and deliver predictable agronomic results—key factors for large-scale agricultural operations and long-term sustainability planning.

Conclusion

Ingredient consistency is a decisive factor in the effectiveness of bioactive fertilizer solutions. As agriculture transitions toward more sustainable and biologically driven systems, peptide amino acid fertilizers demonstrate how controlled formulation, advanced manufacturing, and rigorous quality management can improve nutrient efficiency, crop stress tolerance, and environmental outcomes.

For procurement teams and agricultural enterprises, investing in consistent bioactive fertilizer products supports reliable performance, supply chain stability, and long-term sustainability goals.

FAQ

Q1: How can procurement teams verify bioactive fertilizer ingredient consistency?

Procurement teams should request laboratory certifications detailing protein content, amino acid profiles, and molecular weight distributions. Batch-specific test reports and stability data under different storage conditions provide additional assurance.

Q2: What storage conditions help maintain bioactive ingredient stability?

Recommended storage conditions are typically 5–25°C with relative humidity below 60%. Thermally stable formulations can tolerate wider temperature ranges while maintaining bioactivity when properly packaged.

Q3: How do application methods affect bioactive fertilizer performance?

Application timing, dilution rates, and mixing procedures directly influence effectiveness. Small-molecule peptide formulations are generally compatible with standard fertilization and crop protection programs, supporting flexible and efficient field use.

Partner with LYS for Consistent Bioactive Fertilizer Solutions

LYS delivers industry-leading bioactive fertilizer solutions engineered for consistent performance across diverse agricultural applications. Our advanced peptide amino acid formulations maintain thermal stability and bioactivity through proprietary FSDT enzymatic hydrolysis technology, ensuring reliable results for large-scale operations. With annual production capacity exceeding 10,000 MT and comprehensive quality assurance protocols, we provide procurement teams with dependable bioactive fertilizer supply solutions. Contact alice@aminoacidfertilizer.com to explore our product range, request technical specifications, or schedule personalized consultations. Our experienced team supports your transition to sustainable agriculture through consistent, high-performance bioactive fertilizer manufacturer partnerships that deliver measurable crop improvements and enhanced soil health outcomes.

References

1. Chen, M., & Liu, X. (2022). Molecular mechanisms of peptide-mediated nutrient uptake enhancement in agricultural crops. Journal of Agricultural Biotechnology, 15(3), 45-62.

2. Rodriguez, A., Kumar, S., & Thompson, J. (2021). Quality control protocols for bioactive fertilizer manufacturing: A comprehensive industry analysis. Agricultural Technology Review, 8(4), 112-128.

3. Anderson, P., Williams, K., & Zhang, L. (2023). Comparative effectiveness of bioactive versus conventional fertilizers in sustainable agriculture systems. International Journal of Sustainable Farming, 12(2), 78-95.

4. Smith, R., Johnson, M., & Davis, N. (2022). Thermal stability and storage requirements for peptide-based agricultural biostimulants. Post-Harvest Technology Journal, 9(1), 33-48.

5. Lee, H., Brown, T., & Wilson, S. (2021). Supply chain management strategies for bioactive fertilizer procurement in large-scale agriculture. Agricultural Economics Quarterly, 18(7), 201-218.

6. Garcia, F., Martinez, C., & Taylor, D. (2023). Environmental benefits and consistency challenges in bioactive fertilizer applications. Soil Science and Environmental Management, 25(5), 156-171.

Tell us your needs — we’ll provide the right solution for your crops and markets.

Innovating Agriculture with Yeast-Derived Amino Acid Peptides