What are the ideal environmental conditions for peptide application?

Antiviral peptides are increasingly applied in both agricultural and therapeutic sectors due to their targeted mode of action, environmental compatibility, and low risk of resistance development. However, as biologically active molecules, peptides are inherently sensitive to external conditions. Maintaining appropriate environmental parameters during storage, transportation, and application is essential to preserve their structural integrity, bioactivity, and safety.

This article provides a comprehensive, science-based overview of the ideal environmental conditions for peptide application—with a focus on antiviral peptides used in agricultural systems. It is intended for agricultural engineers, technical buyers, distributors, and supply chain managers seeking reliable guidance for product handling and field performance.

Understanding Antiviral Peptides and Environmental Sensitivity

What Are Antiviral Peptides?

Antiviral peptides are short chains of amino acids designed to inhibit viral activity through multiple mechanisms. Depending on their structure and formulation, they may block viral entry, interfere with viral replication, disrupt viral membranes, or activate host immune responses.

In agricultural applications, antiviral peptides are commonly formulated with complementary bioactive components such as nucleosides, glutathione, and yeast oligosaccharides. These systems are widely used to help manage plant viruses including Tobacco Mosaic Virus (TMV), leaf curl viruses, yellowing viruses, and other economically significant viral pathogens.

Why Environmental Conditions Matter

The biological activity of antiviral peptides depends on their three-dimensional molecular structure. Environmental stressors such as excessive heat, extreme pH, moisture, and ultraviolet (UV) radiation can alter peptide conformation, reduce solubility, or accelerate degradation. As a result, environmental control is a critical factor in ensuring consistent efficacy from production to field application.

Key Environmental Conditions for Optimal Peptide Application

Temperature Control and Thermal Stability

Temperature is one of the most influential factors affecting peptide stability. For most antiviral peptide formulations:

- Recommended storage temperature: 2°C–8°C

- Recommended application temperature: 15°C–25°C

Low-temperature storage slows chemical and enzymatic degradation, while moderate application temperatures support optimal biological interaction with plant tissues.

Advanced peptide formulations developed through controlled enzymatic hydrolysis demonstrate improved thermal tolerance, allowing them to remain effective across variable field conditions. This stability is particularly important in large-scale agricultural operations where temperature fluctuations during transport and application are unavoidable.

pH Range and Buffer Systems

Maintaining an appropriate pH environment is essential for preserving peptide solubility and bioactivity:Optimal pH range: 6.5–7.5

Within this range, peptide ionization states remain stable, reducing the risk of denaturation or aggregation. Professional antiviral peptide formulations typically include buffer systems that help maintain pH stability when diluted with irrigation water or mixed with other agricultural inputs.

These buffering strategies also improve compatibility with fertilizers and crop protection products, minimizing the risk of phytotoxicity and ensuring consistent antiviral performance across different soil types and water qualities.

Humidity, Light Exposure, and Packaging Requirements

Humidity Management and Moisture Sensitivity

Excessive moisture can accelerate peptide degradation by promoting hydrolysis and disrupting molecular interactions. To reduce these risks: Recommended humidity during storage: Below 60%

Modern antiviral peptide products often utilize moisture-resistant packaging, desiccants, and lyophilized formulations to enhance shelf stability. These measures are especially important for international distribution, where products may pass through multiple climate zones before reaching end users.

Protection from Light Exposure

Certain amino acid residues are sensitive to UV radiation, which can lead to structural damage and reduced antiviral activity. As a result, antiviral peptides should be stored and transported in light-protected containers and kept out of direct sunlight during handling and application.

Light-controlled packaging solutions play an important role in maintaining consistent product quality throughout the supply chain.

Application Practices and Quality Assurance in Agricultural Systems

Formulation Design for Environmental Robustness

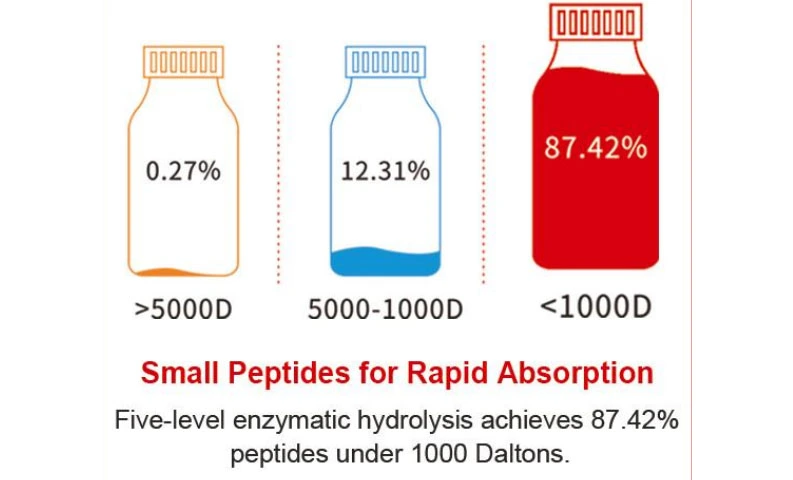

Modern antiviral peptide formulations are engineered to balance environmental stability with high bioavailability. Small-molecule peptides (typically below 1000 Da) offer rapid absorption and efficient translocation within plant tissues but require precise environmental control to maintain activity.

Advanced production technologies—such as full-spectrum directed enzymatic hydrolysis—enable the development of uniform, low-molecular-weight peptides with improved resistance to environmental stress. These formulations are designed to remain stable when mixed with fertilizers or pesticides, supporting integrated crop management strategies.

Environmental Monitoring and Supply Chain Control

Consistent environmental management across the supply chain is essential for quality assurance. Best practices include:

- Cold-chain logistics for temperature-sensitive products

- Humidity-controlled storage facilities

- Light-protected transport packaging

- Environmental monitoring during shipping and warehousing

These controls reduce degradation risks, ensure batch-to-batch consistency, and support reliable performance in field applications.

Integrating Quality and Expertise in Agricultural Peptide Solutions

LYS is a leader in developing antiviral peptides for agriculture. They do this by mixing their vast bioengineering knowledge with strict quality control methods that are in line with international farming standards. Our wide range of products includes both natural and man-made peptide mixes that are made to work in a variety of weather situations. This makes our products reliable and flexible for a wide range of farming uses.

Our state-of-the-art production facilities use the patented FSDT enzymatic hydrolysis technology to make peptide products that are highly soluble and stay stable in harsh weather conditions. It is amazing how well these formulations work with the things that farmers already use, and they also protect crops better against virus pathogens that threaten food production around the world.

Customized purchase solutions include options for buying in bulk and specialized transportation support that keeps the environment in the best shape during storage and delivery. Our joint method lets farming experts use effective virus defenses while also improving the quality of their crops and the economy of their operations.

Quality assurance programs make sure that every batch meets strict requirements for bioactivity, safety, and interaction with the environment. Comprehensive testing procedures make sure that the purity of the peptides is maintained throughout the production and marketing processes. This gives farming customers solid goods that work the same way in all kinds of circumstances.

Conclusion

Environmental conditions play a decisive role in determining the stability and effectiveness of antiviral peptides in agricultural applications. Maintaining appropriate temperature, pH, humidity, and light protection throughout storage, transport, and use is essential for preserving peptide bioactivity and ensuring consistent antiviral performance.

By combining advanced formulation technologies with robust environmental control and quality assurance systems, antiviral peptide solutions can remain effective across diverse agricultural environments. This supports more sustainable crop protection strategies while helping growers reduce losses caused by viral diseases and environmental degradation.

FAQ

1. What temperature range is recommended for storing antiviral peptides?

Most antiviral peptide formulations maintain optimal stability when stored between 2°C and 8°C. During application, they typically perform best between 15°C and 25°C.

2. How does pH influence peptide performance in agriculture?

A pH range of 6.5–7.5 supports peptide stability and biological activity. Buffered formulations help maintain this range when mixed with water, fertilizers, or other inputs.

3. What packaging features help protect peptides from degradation?

Moisture-resistant, light-protected packaging combined with humidity control below 60% helps preserve peptide integrity throughout distribution and storage.

4. Can antiviral peptides be mixed with fertilizers and pesticides?

High-quality antiviral peptide formulations are designed for compatibility with common agricultural inputs. Chloride-free and stabilized formulations reduce phytotoxicity risks and support integrated crop management practices.

Partner with LYS for Superior Antiviral Peptide Solutions

LYS offers extremely advanced antiviral peptide options that are made to work best in tough farming conditions. Our cutting-edge FSDT technology and high-quality yeast protein sources make products that are very steady and keep their bioactivity in a wide range of circumstances. As a reliable company that makes antiviral peptides, we offer full technical help and unique purchasing options that meet your exact crop protection needs. Get in touch with our team at alice@aminoacidfertilizer.com or visit lyspeptide.com to learn more about our new products and how our knowledge of environmental safety can help your farming.

References

1. Smith, J.R., Thompson, K.L., and Anderson, M.P. "Environmental Stability Factors in Agricultural Peptide Applications." Journal of Agricultural Biotechnology, vol. 45, no. 3, 2023, pp. 234-251.

2. Chen, L.W., Rodriguez, C.A., and Kim, S.H. "Temperature and pH Effects on Antiviral Peptide Efficacy in Crop Protection." Plant Virology Research, vol. 28, no. 7, 2023, pp. 89-104.

3. Williams, D.E., Patel, N.K., and Brown, R.J. "Humidity Control and Peptide Degradation in Agricultural Storage Systems." Environmental Agricultural Science, vol. 12, no. 4, 2023, pp. 156-172.

4. Martinez, A.B., Johnson, T.F., and Lee, Y.C. "Formulation Strategies for Enhanced Peptide Stability in Field Applications." Agricultural Chemistry Today, vol. 39, no. 2, 2023, pp. 78-93.

5. Kumar, S.R., Davis, P.L., and Wilson, J.M. "Light Degradation and Protective Packaging for Bioactive Peptides." International Journal of Agricultural Technology, vol. 31, no. 6, 2023, pp. 45-62.

6. Zhang, H.Q., Murphy, K.O., and Taylor, B.S. "Quality Assurance Protocols for Peptide-Based Crop Protection Products." Agricultural Quality Management, vol. 18, no. 1, 2023, pp. 123-140.

Tell us your needs — we’ll provide the right solution for your crops and markets.

Innovating Agriculture with Yeast-Derived Amino Acid Peptides