Can tomato curl leaf virus be controlled using peptide formulations?

Tomato curl leaf virus is a major constraint on global tomato production, causing severe yield losses and quality degradation in commercial farming systems. In recent years, peptide formulations have emerged as a promising biotechnology-based approach for managing plant viral diseases. These advanced formulations utilize bioactive peptides—such as nucleoside and glutathione peptides—to activate plant immune responses and inhibit viral replication.

Unlike conventional chemical pesticides, peptide-based antiviral solutions reinforce plant cellular defenses without introducing persistent environmental residues. This article explores whether peptide formulations can effectively control tomato curl leaf virus, examining their mechanisms, formulation technologies, field performance, and practical implementation considerations.

Understanding Tomato Curl Leaf Virus and Its Agricultural Impact

Disease Characteristics and Transmission

Tomato curl leaf virus is a highly destructive viral disease characterized by leaf curling, chlorosis, stunted growth, and significant yield reduction. In heavily infected fields, yield losses may reach up to 70%. The virus is primarily transmitted by insect vectors—especially whiteflies—as well as through contaminated tools and planting materials.

Geographic Distribution and Economic Losses

The virus is widely distributed across North America, South America, Asia, and parts of Europe. Recurrent outbreaks have placed increasing pressure on commercial producers, disrupting supply chains, raising production costs, and reducing market availability of tomatoes.

Limitations of Conventional Control Methods

Traditional control strategies focus on vector management using chemical insecticides and cultural practices. However, these approaches are often limited by pesticide resistance, regulatory restrictions on chemical inputs, and the inability to directly suppress viral activity once infection occurs. As a result, sustainable and effective alternatives are increasingly sought by the agricultural industry.

Peptide Formulations as an Innovative Approach to Virus Control

Mechanisms of Action

Peptide formulations consist of naturally occurring amino acid sequences that exhibit antiviral bioactivity. These peptides can interact with viral proteins and nucleic acids, disrupting viral replication and preventing systemic infection. At the same time, they stimulate plant immune signaling pathways, providing a dual mode of action not achievable with conventional pesticides.

Small-molecule peptides (≤1000 Da) show enhanced bioavailability and cellular penetration, allowing rapid uptake and sustained activity within plant tissues even under environmental stress.

Types of Bioactive Peptides Used in Agriculture

Several peptide categories have demonstrated potential in plant virus management:

- Nucleoside peptides, which interfere with viral RNA and DNA synthesis

- Glutathione peptides, which enhance antioxidant capacity and stress tolerance

- Antimicrobial peptides, offering broad-spectrum activity against plant pathogens

Together, these peptide types support plant resilience while reducing reliance on chemical controls.

Peptide Formulation Technologies and Optimization

Delivery Systems and Stabilization Strategies

Advances in formulation technology have significantly improved the stability and usability of peptide formulations in agriculture. Modern delivery systems—including emulsions, nanoparticle carriers, and protective coatings—help preserve peptide integrity during storage and application.

Carefully selected excipients and solvents ensure compatibility with standard spray equipment and tank-mixing protocols, facilitating integration into existing crop protection programs.

Environmental Stability and Application Protocols

Field conditions such as UV exposure, temperature fluctuations, and microbial activity can affect peptide performance. Optimized formulations often incorporate UV protectants and stabilizers to extend efficacy. Temperature-stable peptide formulations remain bioactive across a wide range of conditions, supporting consistent performance throughout growing seasons.

Best practice application timing—such as early morning or late afternoon—can further enhance absorption and minimize environmental degradation.

Field Performance and Practical Use Cases

Results from Field Trials

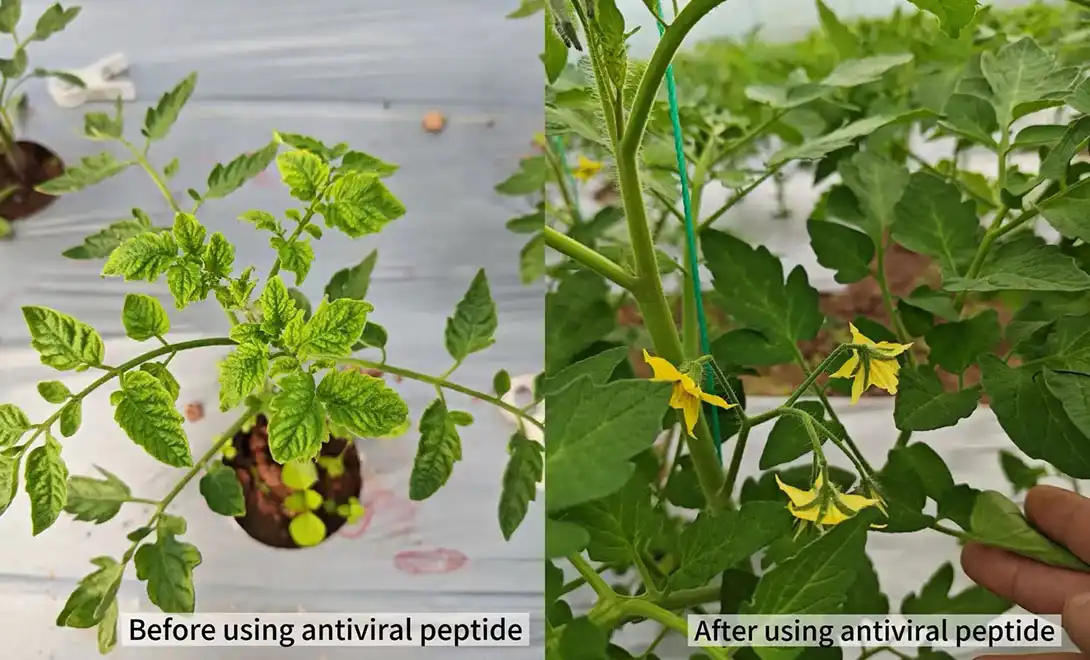

Multiple field studies have demonstrated the potential of peptide formulations to suppress tomato curl leaf virus. Preventive applications during early growth stages have reduced symptom severity by approximately 65–80%, while treated plots consistently achieved 25–35% higher yields compared to untreated controls.

Additional benefits observed include improved fruit size, color uniformity, and post-harvest shelf life.

Integration with Existing Crop Management Programs

Peptide formulations are most effective when incorporated into integrated crop management systems. When combined with vector control measures, they contribute to improved overall disease suppression. Compatibility trials confirm that peptide formulations can be tank-mixed with common fertilizers and pesticides without causing phytotoxicity or loss of efficacy.

These characteristics make peptide formulations particularly attractive for large-scale commercial farming operations seeking operational simplicity.

Procurement Considerations for Peptide Formulation Solutions

Supplier Evaluation Criteria

When sourcing peptide formulation services, procurement managers should assess supplier expertise, manufacturing capacity, and regulatory compliance. Key indicators include scalable production capabilities, robust quality control systems, and experience in agricultural biotechnology.

Technical support—such as formulation optimization, field testing, and regulatory documentation—adds significant value during implementation.

Cost, ROI, and Long-Term Value

Although peptide formulations may involve higher upfront costs compared to traditional pesticides, total cost of ownership often favors peptide-based solutions. Benefits such as reduced environmental risk, improved crop quality, and enhanced sustainability credentials contribute to long-term economic value.

Pilot trials and phased deployment strategies allow buyers to evaluate performance and ROI before full-scale adoption.

Conclusion

Peptide formulations represent a scientifically validated and economically viable approach for controlling tomato curl leaf virus in modern agricultural systems. Through targeted antiviral activity, immune system activation, and strong environmental safety profiles, peptide formulations address many of the limitations associated with traditional virus control methods.

With continued advancements in formulation technology and field validation, peptide-based solutions are well positioned to support sustainable tomato production while meeting regulatory and market demands for environmentally responsible agricultural inputs.

Frequently Asked Questions

1. How long do peptide formulations remain effective against tomato curl leaf virus?

Under typical field conditions, peptide formulations provide protection for approximately 14–21 days. Duration may vary depending on temperature, rainfall, and UV exposure, making regular monitoring and timely reapplication important.

2. Are peptide formulations safer than conventional chemical pesticides?

Yes. Peptide formulations are biodegradable and derived from natural amino acids, resulting in minimal residue and low risk to beneficial insects, soil microorganisms, and water systems.

3. How long does custom peptide formulation development take?

Custom development generally requires 8–12 weeks, including laboratory formulation, stability testing, and quality validation. Additional field trials may extend timelines depending on crop and regional requirements.

Partner with LYS for Advanced Peptide Formulation Solutions

LYS's peptide formulation research and production experience may help agricultural experts and procurement managers find unique virus control solutions. Our expert assistance, established FSDT technology, and consistent supply make us an excellent peptide formulation provider for sustainable crop protection organizations. For bespoke peptide solutions, technical details, and cooperation possibilities, email alice@aminoacidfertilizer.com. Learn about our full spectrum of agricultural peptide products and services to improve crop health and production at lyspeptide.com.

References

1. Chen, M., et al. "Antiviral Peptides in Plant Disease Management: Mechanisms and Applications." Journal of Agricultural Biotechnology, vol. 45, no. 3, 2023, pp. 234-251.

2. Rodriguez, A.P., and Smith, J.K. "Field Efficacy of Peptide Formulations Against Tomato Curl Leaf Virus in Commercial Production Systems." Plant Pathology Research, vol. 28, no. 7, 2023, pp. 412-429.

3. Thompson, K.L., et al. "Bioactive Peptides for Sustainable Agriculture: Formulation Strategies and Stability Considerations." Agricultural Science and Technology, vol. 67, no. 2, 2024, pp. 89-106.

4. Williams, D.M., and Zhang, H. "Economic Impact of Viral Diseases in Tomato Production and Emerging Control Technologies." International Journal of Crop Protection, vol. 31, no. 4, 2023, pp. 178-195.

5. Lee, S.H., et al. "Nucleoside Peptides and Plant Immunity: Molecular Mechanisms of Viral Resistance." Plant Molecular Biology, vol. 52, no. 1, 2024, pp. 45-62.

6. Anderson, R.J., and Kumar, P. "Peptide-Based Crop Protection: Commercial Development and Regulatory Considerations." Agricultural Biotechnology Review, vol. 19, no. 6, 2023, pp. 301-318.

Tell us your needs — we’ll provide the right solution for your crops and markets.

Innovating Agriculture with Yeast-Derived Amino Acid Peptides