Enzymatic vs. Acid Hydrolyzed Biostimulants: Understanding the Difference

In modern agriculture, biostimulants have become an important tool for improving crop productivity, nutrient efficiency, and stress tolerance. Among the different categories of biostimulants, protein hydrolysates play a prominent role due to their rich amino acid and peptide content. Within this group, enzymatic hydrolyzed biostimulants and acid hydrolyzed biostimulants represent two distinct production approaches, each resulting in different chemical compositions and agronomic effects.

This article provides a scientifically grounded comparison of enzymatic and acid hydrolyzed biostimulants, focusing on their production processes, bioavailability, amino acid profiles, and crop-specific applications. Understanding these differences can help manufacturers, distributors, and growers make more informed decisions when selecting biostimulants for specific agronomic objectives.

Enzymatic vs. Acid Hydrolyzed Biostimulants: Understanding the Difference

Protein hydrolysates are a crucial component of biostimulants, yielding small molecules that plants can absorb and utilize through the breakdown of complex proteins. The hydrolysis method decisively influences the characteristics of the final product. Specifically, the molecular weight distribution and biological activity of the peptide fragments are key factors distinguishing high-quality biostimulants.

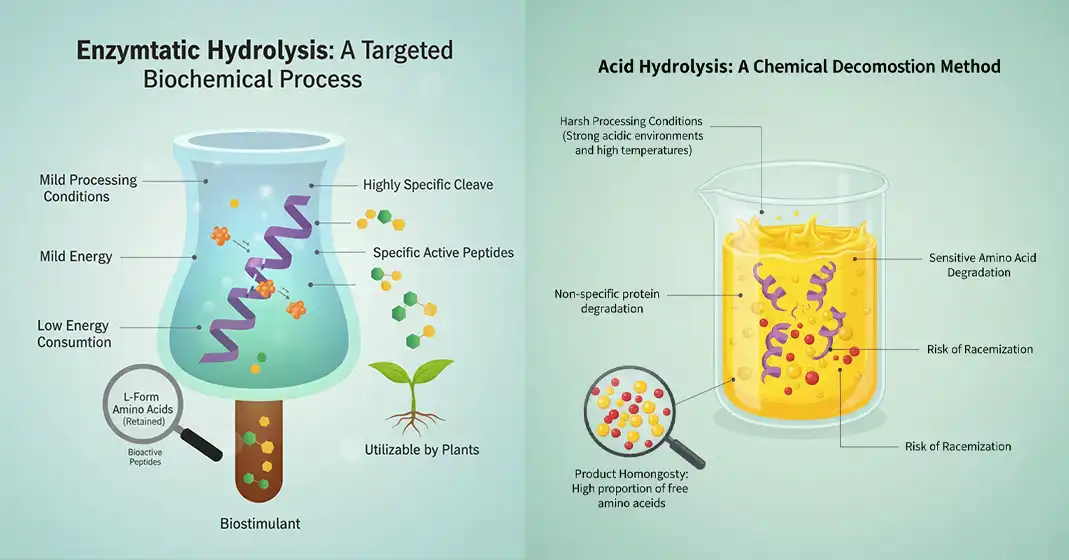

Enzymatic Hydrolysis: A Targeted Biochemical Process

Enzymatic hydrolysis uses specific enzymes to cleave proteins under mild, controlled temperature and pH conditions. This process mimics natural bioreactions, enabling precise control over protein degradation.

Key characteristics of enzymatic hydrolysis include:

- Mild processing conditions: Avoids high temperatures and extreme pH levels, maximizing retention of heat-sensitive functional components such as amino acids, peptides, and endogenous plant growth substances.

- Highly Specific Cleavage: Enables targeted cleavage of specific peptide bonds.

- L-Form Amino Acid Retention: Preserves the biologically active L-form conformation of amino acids, the form directly absorbable and utilizable by plants.

- Formation of Specific Active Peptides: Produces short-chain bioactive peptides within a defined molecular weight range, possessing potential signaling functions.

- Low Energy Consumption and Environmental Sustainability: Minimal energy usage and environmental impact.

As a result, Enzymatically hydrolyzed biostimulants typically contain a balanced blend of free amino acids and bioactive, specific short-chain peptides.

Acid Hydrolysis: A Chemical Decomposition Method

Acid hydrolysis relies on strong acids, such as hydrochloric acid, combined with high temperatures to rapidly break down proteins.While highly efficient, this method exhibits significantly lower selectivity compared to enzymatic hydrolysis.

Typical features of acid hydrolysis include:

- Harsh processing conditions (Strong acidic environments and high temperatures)

- Non-specific protein degradation: Indiscriminate cleavage of peptide bonds.

- Sensitive amino acid degradation: High temperatures and extreme pH levels can degrade crucial amino acids (e.g., tryptophan)

- Risk of racemization: Some L-amino acids (the biologically active form in plants) may convert to less active D-amino acids (racemization), reducing the product's bioactivity.

- Product Homogeneity: The final product contains a high proportion of free amino acids and lacks complex bioactive peptides.

The hydrolysis method directly affects both the composition and biological activity of the resulting biostimulants, making process selection a critical factor in product development.

Enzymatic Hydrolysis vs. Acid Hydrolysis Biostimulants:Impact on Bioavailability and Amino Acid Profiles

The agronomic effectiveness of biostimulants depends not only on nutrient content but also on how efficiently plants can absorb and utilize those nutrients.

Bioavailability and Nutrient Uptake

Bioavailability refers to the ease with which plants absorb and assimilate amino acids and peptides from biostimulants.

Advantages of enzymatic hydrolysis: The resulting small peptide fragments can be directly absorbed through peptide transporters on plant cell membranes, often exhibiting higher absorption efficiency than free amino acids alone. These peptides and amino acids also function as natural chelating agents, enhancing the absorption of other nutrients.

Limitations of acid hydrolysis: Primarily produces free amino acids, which are easily absorbed but lack the synergistic effects and diverse absorption mechanisms provided by bioactive peptides.

Higher bioavailability can improve nutrient use efficiency and potentially reduce reliance on conventional fertilizers.

Amino Acid Quantity and Quality

Enzymatic Hydrolysis Method: Provides a more diverse and complete amino acid profile, maintains amino acids in their natural L-form, and contains a balanced combination of free amino acids and specific bioactive peptides. This balanced structure effectively supports multiple metabolic pathways in plants.

Acid hydrolysis method: The amino acid profile may lack certain amino acids due to harsh conditions, contains a proportion of D-amino acids, and lacks bioactive peptides with signaling functions.

Signaling Molecules and Plant Growth Promotion

Beyond their nutritional value, amino acids and peptides in biostimulants can act as signaling molecules, triggering specific plant responses:

- Enzymatic Hydrolysis: The specific short-chain active peptides produced can act as elicitors, effectively stimulating plant defense mechanisms, promoting growth responses, and enhancing plant stress tolerance and vitality under adverse conditions.

- Acid Hydrolysis: While still providing beneficial free amino acids, it may lack some of the more complex signaling peptides found in enzymatically hydrolyzed products.

Enzymatic hydrolysis processes, particularly the targeted enzymatic hydrolysis employed by LYS biotech, ensure high biological activity and broad-spectrum functionality by controlling peptide molecular weight. Meanwhile,this approach also enables outstanding performance in enhancing crop growth, nutrient absorption, and stress resistance.

Role of Peptides and Signaling Molecules in Plant Growth

Beyond basic nutrition, some components of biostimulants act as signaling molecules that influence plant physiology.

Enzymatic Hydrolysis and Bioactive Peptides

Enzymatic hydrolysis can generate peptides that function as elicitors, stimulating plant defense mechanisms, root development, and stress tolerance. These signaling effects may be particularly relevant under abiotic stress conditions such as drought, salinity, or temperature extremes.

Acid Hydrolysis and Nutritional Support

While acid hydrolyzed biostimulants primarily supply free amino acids, they generally contain fewer complex peptides. Their main contribution lies in providing rapidly available nitrogenous compounds rather than triggering specific physiological signals.

Crop-Specific Responses to Different Hydrolysate Types

The effectiveness of enzymatic and acid hydrolyzed biostimulants can vary depending on crop species, growth stage, and environmental conditions.

Crops Commonly Benefiting from Enzymatic Hydrolysates

Due to their complex composition, enzymatically hydrolyzed biostimulants are often associated with broader physiological benefits and are commonly applied to:

- Fruit crops: citrus, grapes, berries (quality, color, stress tolerance)

- Vegetables: tomatoes, leafy greens, root vegetables (growth uniformity and nutrient density)

- Cereals: wheat and rice (yield stability and grain quality)

- Legumes: soybeans, peas, and beans (nodulation and protein accumulation)

These products are frequently used during critical growth stages or stress-prone periods.

Crops Commonly Benefiting from Acid Hydrolysates

Acid hydrolyzed biostimulants may be advantageous in situations where rapid nutrient availability is required, such as:

- Fast-growing crops: leafy vegetables and microgreens

- Low-fertility soils: maize and sorghum

- Controlled environments: greenhouse and hydroponic systems

Their high free amino acid content can support quick metabolic responses and early growth.

Practical Considerations for Selection

When choosing between enzymatic and acid hydrolyzed biostimulants, several key agronomic factors need to be taken into consideration, including the target crop type and its current growth stage, the presence of abiotic or nutritional stress in the cultivation environment, the inherent fertility and structural properties of the soil, as well as the core production goals such as yield improvement, quality enhancement or stress resistance. By aligning the right type of biostimulant with these specific agronomic needs, growers can effectively maximize the product’s performance and optimize their return on investment.

Conclusion

Enzymatic and acid hydrolyzed biostimulants represent two distinct approaches to producing protein-based biostimulants, each with specific advantages and limitations. Enzymatic hydrolysis offers a controlled process that preserves bioactive peptides and a wide range of L-amino acids, making it suitable for crops requiring precise physiological regulation. Acid hydrolysis, while less selective, provides readily available free amino acids that can support rapid growth under certain conditions.

As agriculture faces increasing challenges related to climate variability, soil degradation, and sustainability, selecting the appropriate type of biostimulant becomes increasingly important. A clear understanding of hydrolysis methods allows stakeholders across the agricultural value chain to make informed, science-based decisions.

FAQs

Q1: How do enzymatic hydrolyzed biostimulants differ from traditional fertilizers?

A: Enzymatic hydrolyzed biostimulants contain a complex blend of peptides and amino acids that not as it were give supplements but also act as signaling particles to improve plant development and stretch resilience. Not at all like conventional fertilizers that basically supply essential nutrients, these biostimulants can trigger particular physiological reactions in plants, leading to improved generally health and productivity.

Q2: Are enzymatic hydrolyzed biostimulants safe for organic farming?

A: Numerous enzymatic hydrolyzed biostimulants are without a doubt reasonable for organic farming, as they are derived from common protein sources and prepared using organic methods. In any case, it's basic to check particular item certifications and comply with local environmental farming regulations, as requirements may change by region.

Q3: How often should enzymatic hydrolyzed biostimulants be applied to crops?

A: The application recurrence of enzymatic hydrolyzed biostimulants depends on different variables, including trim sort, development organize, and natural conditions. By and large, applications are most advantageous during key development stages or periods of growth. For particular suggestions, it's best to consult with agronomic specialists or refer to item rules custom-fitted to your specific crops and growing conditions.

Unlock Your Crops' Potential with Advanced Enzymatic hydrolysis Biostimulants | LYS Biotech

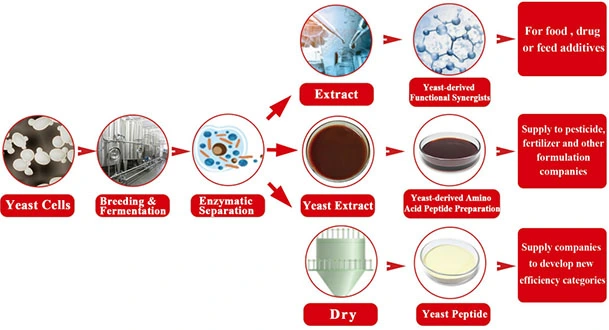

With more than 70 years of experience in yeast enzymatic hydrolysis technology, LYS Biotech develops advanced biostimulant solutions based on proprietary enzymatic hydrolysis processes. These technologies are designed to preserve valuable peptides and amino acids, supporting crop performance under diverse agronomic conditions.

LYS Biotech works with agrochemical manufacturers, distributors, and large-scale growers worldwide, providing consistent, high-quality biostimulant ingredients aligned with modern sustainable agriculture practices.For more information about enzymatic biostimulant solutions and technical support, please contact our team at alice@aminoacidfertilizer.com

References

1. Johnson, A. R., & Smith, B. T. (2022). Comparative analysis of enzymatic and acid hydrolyzed biostimulants in sustainable agriculture. Journal of Plant Nutrition and Soil Science, 185(3), 456-470.

2. Garcia-Martinez, A. M., et al. (2021). Enzymatic hydrolysis: A superior approach for producing bioactive peptides in agricultural applications. Frontiers in Plant Science, 12, 658978.

3. Wilson, H. T., & Brown, K. L. (2023). Amino acid profiles and plant growth promotion: Insights from hydrolysate biostimulants. Plant Physiology and Biochemistry, 178, 114-127.

4. Colla, G., & Rouphael, Y. (2020). Biostimulants in horticulture. Scientia Horticulturae, 267, 109324.

5. Thompson, R. S., et al. (2022). Enhancing crop resilience: The role of enzymatically derived peptides in modern agriculture. Crop Science, 62(4), 1589-1605.

6. Lee, J. W., & Chen, X. Y. (2023). Optimizing biostimulant application strategies for diverse cropping systems: A comprehensive review. Agronomy, 13(5), 1156.

Tell us your needs — we’ll provide the right solution for your crops and markets.

Innovating Agriculture with Yeast-Derived Amino Acid Peptides