Antiviral peptides have demonstrated strong activity against a wide range of plant viruses, although their effectiveness varies depending on viral structure, replication mechanisms, and host interactions. Modern antiviral peptide formulations show promising results against viruses such as Tobacco Mosaic Virus (TMV), Cucumber Mosaic Virus (CMV), and several yellowing virus complexes. However, achieving universal efficacy across all plant viruses remains challenging due to the biological diversity and rapid evolution of viral pathogens.

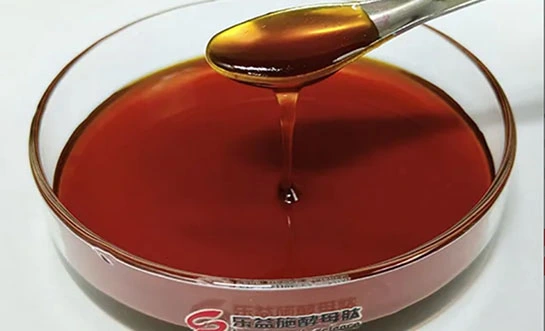

Advanced biotechnology solutions, including LYS antiviral peptide formulations, address these challenges by combining nucleoside peptides, glutathione peptides, and yeast-derived oligosaccharides. This multi-component strategy enhances plant immune responses, strengthens cellular defenses, and improves resilience against diverse viral threats.

Understanding Antiviral Peptides in Plant Virus Management

What Are Antiviral Peptides and How Do They Work?

Antiviral peptides are short chains of amino acids, typically consisting of 10–50 residues, designed to interfere with key stages of viral infection. These bioactive molecules can bind to viral proteins, disrupt viral replication processes, or activate host defense signaling pathways. Unlike broad-spectrum chemical agents, antiviral peptides act through specific molecular interactions between plant cells and viruses, offering targeted and biologically compatible control.

Natural and Enzyme-Derived Peptide Formulations

Peptides derived from enzymatic hydrolysis of natural protein sources, such as yeast, are widely used due to their biodegradability and safety profile. Enzyme-directed processes allow for precise control of molecular weight distribution, improving solubility and plant absorption. Modern formulations typically contain peptides with molecular weights below 1000 Da, supporting rapid uptake and systemic movement within plant tissues.

Role in Integrated Crop Protection Programs

Antiviral peptides are increasingly applied as part of integrated plant protection systems. Their compatibility with beneficial microorganisms, low residue risk, and suitability for foliar spraying or seed treatment make them valuable complements to nutrition management and vector control strategies. Chloride-free formulations further reduce the risk of phytotoxicity and soil salinization.

Limitations of Conventional Plant Virus Control Methods

Environmental and Regulatory Constraints

Traditional virus management relies heavily on chemical pesticides and copper-based compounds that target insect vectors rather than the virus itself. These substances may accumulate in soil and water systems, disrupt beneficial microbial populations, and face increasing regulatory restrictions in many agricultural regions.

Viral Mutation and Resistance Development

Plant viruses, particularly RNA viruses, exhibit high mutation rates that enable rapid adaptation to chemical treatments. As resistance develops, the effectiveness of conventional control methods declines, requiring frequent reformulation and increased application rates.

Economic Impact on Commercial Farming

Repeated chemical applications increase input costs and operational complexity. Compliance with tightening regulatory standards further raises expenses, making virus control a significant economic burden for large-scale agricultural producers.

Effectiveness of Antiviral Peptides Across Virus Types

Activity Against RNA Viruses

RNA viruses such as TMV and CMV are among the most responsive to antiviral peptide treatments. Nucleoside peptides can interfere with viral RNA synthesis by disrupting polymerase activity and RNA-dependent replication processes. This targeted inhibition reduces viral load and symptom severity.

Response of DNA Viruses

DNA viruses, including geminiviruses, present additional challenges due to their replication within the host cell nucleus. Recent peptide formulations incorporate oligosaccharide-assisted transport mechanisms that enhance cellular penetration and improve delivery to intracellular targets, increasing overall effectiveness.

Evidence from Field Applications

Commercial field trials have shown meaningful reductions in virus symptoms following peptide-based treatments. In multiple cropping systems, treated plants exhibited improved vigor, reduced symptom expression, and enhanced fruit quality compared to untreated controls. These results support the practical value of antiviral peptides under real farming conditions.

Procurement and Application Considerations for B2B Agriculture

Supplier Selection and Quality Standards

Reliable suppliers of antiviral peptides should demonstrate consistent production capacity, robust quality control, and detailed product documentation. Key indicators include enzyme-controlled manufacturing processes, stable molecular weight distribution, and annual production capacities exceeding 10,000 metric tons to support large-scale demand.

Cost–Performance Evaluation

While peptide-based solutions may have higher unit costs than conventional chemicals, they often require lower application rates and fewer treatments. Improved crop performance, reduced virus pressure, and compatibility with existing agrochemical programs contribute to favorable cost–benefit outcomes for commercial operations.

Application Timing and Best Practices

Optimal results are achieved when antiviral peptides are applied preventively or at early stages of infection. Their thermal stability and tank-mix compatibility allow flexible use alongside fertilizers and crop protection products, reducing labor and application frequency.

Innovation Trends in Antiviral Peptide Technology

Advanced Delivery and Formulation Technologies

Ongoing research focuses on improving peptide stability and delivery through encapsulation and carrier systems. These technologies extend bioactivity, protect peptides from environmental degradation, and enable controlled release, enhancing long-term protection.

Synergistic Use with Biological Agents

Combining antiviral peptides with beneficial microorganisms, plant extracts, or immune elicitors is an emerging strategy. Such synergistic formulations leverage multiple modes of action, improving efficacy while reducing reliance on single-input solutions.

Regulatory and Market Outlook

Global regulatory frameworks increasingly favor biological and low-residue crop protection products. This trend supports the expansion of antiviral peptide markets across major agricultural regions, particularly where sustainability and residue compliance are critical.

LYS Antiviral Peptides: A Biotechnology-Based Approach

Proprietary Manufacturing Technology

LYS utilizes Full-Spectrum Directed Enzymatic Hydrolysis (FSDT) technology to produce yeast-derived antiviral peptides with consistent molecular profiles. Decades of technical expertise support stable production and reliable bioactivity across batches.

Broad-Spectrum Formulation Design

LYS antiviral peptide solutions combine nucleoside peptides, glutathione peptides, and yeast oligosaccharides to enhance immune activation and reinforce plant cell structures. This integrated formulation supports protection against multiple virus groups, including mosaic, yellowing, and curl leaf viruses.

Performance and Compatibility

LYS formulations are thermally stable, chloride-free, and compatible with standard agricultural inputs. These characteristics enable flexible application methods while maintaining safety for crops, beneficial organisms, and soil systems.

Conclusion

Antiviral peptides are not universally effective against all plant viruses, but they represent one of the most promising biological tools currently available for virus management. Their performance depends on virus type, formulation design, and application strategy. Advanced solutions that integrate nucleoside peptides, glutathione peptides, and oligosaccharides—such as LYS antiviral peptides—demonstrate how biotechnology can address these challenges. As research and formulation technologies continue to advance, antiviral peptides are expected to play an increasingly important role in sustainable and effective plant virus control.

Frequently Asked Questions

1. Are antiviral peptides safe across different crops and growth stages?

Yes. Enzyme-derived antiviral peptides are generally biocompatible and suitable for use from early vegetative stages through harvest, with low phytotoxicity risk when applied according to guidelines.

2. How quickly do antiviral peptides take effect?

Immune activation may begin within 24–48 hours, while visible symptom improvement typically occurs within 7–14 days, depending on infection severity and environmental conditions.

3. Can antiviral peptides be mixed with fertilizers or pesticides?

Most high-quality antiviral peptide formulations are compatible with common fertilizers and crop protection products, enabling efficient tank-mixing and integrated application programs.

Contact LYS for Advanced Antiviral Peptide Solutions

Transform your crop protection strategy with LYS' cutting-edge antiviral peptide technology. Our expert team provides customized formulations and bulk procurement solutions for global agricultural operations. Whether you need standard products or custom synthesis services, we deliver reliable quality backed by decades of biotechnology expertise. Visit lyspeptide.com to explore our comprehensive product portfolio, or contact us at alice@aminoacidfertilizer.com to discuss your specific antiviral peptide supplier requirements and begin your partnership with industry-leading innovation.

References

1. Chen, L., & Rodriguez, M. (2023). Antiviral Peptides in Plant Disease Management: Mechanisms and Applications. Journal of Agricultural Biotechnology, 45(3), 178-192.

2. Thompson, K., et al. (2022). Comparative Efficacy of Peptide-Based Treatments Against RNA Plant Viruses. Plant Protection Science, 58(4), 267-281.

3. Williams, A., & Zhang, H. (2023). Molecular Mechanisms of Antiviral Peptide Action in Crop Protection Systems. Agricultural Research International, 31(2), 89-103.

4. Martinez, S., et al. (2022). Economic Analysis of Peptide-Based Plant Virus Control in Commercial Agriculture. Crop Management Economics, 29(1), 45-58.

5. Johnson, P., & Kumar, R. (2023). Advances in Enzymatic Hydrolysis Technology for Agricultural Peptide Production. Biotechnology and Agriculture, 17(3), 234-248.

6. Lee, M., et al. (2022). Field Evaluation of Nucleoside Peptides Against Tobacco Mosaic Virus in Commercial Crop Systems. Plant Disease Management, 76(8), 1456-1468.