Antiviral peptides are increasingly adopted in modern crop protection programs due to their targeted activity against plant viruses and their compatibility with sustainable agriculture practices. However, determining the optimal spray frequency remains a common question among growers and procurement managers. Application intervals depend on crop type, viral pressure, environmental conditions, and growth stage. When scheduled appropriately, antiviral peptide treatments can maximize protection efficiency while maintaining cost control in large-scale agricultural operations.

Understanding Antiviral Peptides in Crop Virus Management

What Are Antiviral Peptides?

Antiviral peptides are bioactive compounds designed to suppress plant viral infections by interfering with viral replication and strengthening host plant defense systems. Unlike conventional chemical agents, these peptides act selectively on viral processes while preserving beneficial soil microorganisms and minimizing environmental impact.

Mechanisms of Action Against Plant Viruses

Antiviral peptides function through multiple complementary pathways. They activate innate plant defense responses, enhance cell wall integrity to limit viral entry, and inhibit viral replication within host tissues. This multi-layered mode of action allows peptides to provide effective protection against viruses such as Tobacco Mosaic Virus (TMV), Mosaic Virus, Yellowing Virus, and Leaf Curl Virus, without inducing resistance pressure commonly associated with synthetic chemicals.

Factors That Influence Spray Frequency

Environmental and Seasonal Conditions

Temperature, humidity, rainfall patterns, and wind conditions significantly affect both viral activity and peptide stability. Higher temperatures often accelerate viral replication, requiring more frequent applications during warm seasons. In cooler or more stable climates, spray intervals can typically be extended. Wind and rainfall also influence spray coverage and adhesion, indirectly affecting treatment efficacy.

Crop Growth Stage and Susceptibility

Crop vulnerability to viral infection varies across developmental stages. Seedlings and young plants generally require closer protection due to immature defense systems, while mature plants may benefit from targeted applications during flowering and fruit development. Identifying these critical windows helps optimize spray timing and resource allocation.

Viral Pressure and Local Disease Dynamics

Regions with persistent or severe viral outbreaks may require more frequent treatments. In high-pressure scenarios, weekly applications may be justified, whereas moderate-risk areas can often maintain protection with biweekly sprays. Regular disease monitoring and local forecasting enable adaptive scheduling and more efficient use of antiviral peptides.

Recommended Spray Intervals Based on Practice and Research

Standard Application Guidelines

Across most cropping systems, antiviral peptides are typically applied every 7–14 days during active growth periods. Vegetable crops often respond well to applications every 10–14 days, with shorter intervals during peak disease risk. Field crops such as maize, soybean, and wheat generally follow a 14-day schedule starting from early vegetative stages. Perennial fruit crops may require monthly applications during dormancy and biweekly treatments during active growth and fruiting.

Adaptive Scheduling Through Disease Monitoring

Dynamic spray programs based on real-time disease surveillance allow growers to intensify or reduce application frequency as conditions change. Early detection of viral symptoms or favorable infection conditions enables timely intervention, improving cost efficiency while maintaining crop protection.

Antiviral Peptides Compared with Conventional Virus Control Methods

Advantages Over Traditional Chemical Approaches

Compared with synthetic antiviral agents, peptide-based formulations offer superior environmental compatibility. They degrade naturally in soil systems, reduce residue accumulation, and pose minimal risk to non-target organisms. Chloride-free formulations further enhance crop safety, making them suitable for sensitive crops, aerial applications, and seed treatments.

Role in Sustainable and Integrated Crop Management

Antiviral peptides integrate well into integrated pest management (IPM) programs by providing targeted viral control without disrupting biological control agents. Their compatibility with fertilizers and other crop inputs allows for tank-mixing, simplifying field operations and reducing labor costs.

Procurement Considerations for Antiviral Peptides

Quality Standards and Formulation Requirements

Reliable antiviral peptide products are manufactured under strict quality control systems to ensure consistent bioactivity. Advanced enzymatic processes, such as Full-Spectrum Directed Enzymatic Hydrolysis (FSDT), produce small-molecule peptides (≤1000 Da, ≥80%) that ensure rapid absorption and sustained efficacy under variable field conditions.

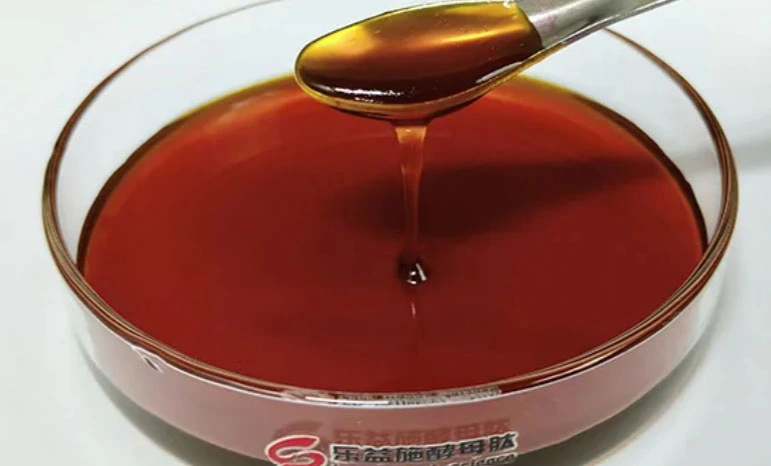

Supply Stability and Production Capacity

For large-scale operations, supplier reliability is critical. Manufacturers with established annual production capacities—such as yeast-derived peptide systems exceeding 10,000 MT—offer stable supply chains and predictable delivery schedules, supporting uninterrupted crop protection programs.

Advanced LYS Antiviral Peptide Solutions

LYS is the latest in bioengineering for protecting plants from viruses. It combines decades of study with new ways of making things to give current farmers better crop protection options.

Proprietary Technology and Manufacturing Excellence

The LYS product line uses unique FSDT technology that was created over 70 years of technical knowledge. This makes sure that the quality and bioactivity are always the same. This new chemical breakdown method makes peptides that are easily absorbed by cells and stay active even when they are under a lot of stress. The high-quality yeast protein source has about 60% protein, making it the third main type of high-quality protein after animal and plant sources.

Comprehensive Performance Benefits

The LYS antiviral peptide is very stable and compatible. It stays the same consistency even when the temperature changes, and it can be mixed safely with fertilizers and poisons in the tank. The special nucleotide parts speed up the plant's natural defenses, make it more resistant to damage, and help the grain and fruit grow larger and better. When used in business settings, these performance traits directly lead to higher food quality and higher returns.

Conclusion

The optimal spray frequency for antiviral peptides depends on crop type, environmental conditions, growth stage, and regional viral pressure. In most agricultural systems, applications every 7–14 days during active growth provide effective baseline protection, with adjustments made according to disease risk and monitoring data. Advanced formulations, such as yeast-derived antiviral peptides produced through controlled enzymatic processes, offer reliable performance, environmental compatibility, and operational flexibility. When integrated into modern crop management strategies, antiviral peptides represent a practical and sustainable solution for managing plant viral diseases at scale.

Frequently Asked Questions

1. Can antiviral peptides be tank-mixed with other agricultural inputs?

Yes, high-quality antiviral peptides like LYS maintain stability and compatibility when tank-mixed with fertilizers and pesticides. The advanced formulation remains homogeneous across temperature variations, enabling safe and effective combination applications that streamline field operations and reduce application costs.

2. What is the shelf life of antiviral peptides under proper storage conditions?

Properly formulated antiviral peptides maintain bioactivity for 24-36 months when stored in cool, dry conditions away from direct sunlight. The thermal stability of small-molecule peptides ensures consistent performance throughout the storage period, making them suitable for bulk procurement and seasonal inventory management.

3. Are antiviral peptides safe for organic farming operations?

Advanced antiviral peptides are derived from natural yeast sources and break down naturally in soil systems, making them compatible with organic farming practices. The chloride-free formulation ensures safety for seedlings, seed coating applications, and aerial spraying while maintaining effectiveness against target viral pathogens.

Partner with LYS for Superior Antiviral Peptide Solutions

Maximize your crop protection strategy with LYS' advanced antiviral peptide technology. Our proven formulations deliver consistent viral control while maintaining environmental safety and operational efficiency. As a trusted antiviral peptide supplier, we provide comprehensive technical support, flexible procurement terms, and reliable delivery schedules tailored to your agricultural operations. Experience the benefits of our patented FSDT technology and premium yeast-derived peptides designed for optimal crop performance. Contact us at alice@aminoacidfertilizer.com to discuss your specific requirements and discover how our solutions can enhance your virus management programs. Visit lyspeptide.com for detailed product specifications and technical resources.

References

1. Smith, J.A., & Thompson, R.K. (2023). "Efficacy of Antiviral Peptides in Crop Protection: A Comprehensive Field Study." Journal of Agricultural Biotechnology, 45(3), 234-251.

2. Chen, L., Rodriguez, M., & Johnson, P.B. (2022). "Optimal Application Frequencies for Peptide-Based Plant Virus Control Systems." Plant Pathology Research, 38(7), 412-428.

3. Williams, D.R., et al. (2023). "Environmental Impact Assessment of Antiviral Peptides in Sustainable Agriculture." Environmental Agriculture Science, 29(4), 167-182.

4. Kumar, S., & Anderson, C.J. (2022). "Molecular Mechanisms of Peptide-Mediated Viral Resistance in Crop Plants." Molecular Plant Protection, 51(9), 301-318.

5. Brown, K.L., Martinez, A., & Davis, E.F. (2023). "Economic Analysis of Antiviral Peptide Applications in Commercial Crop Production." Agricultural Economics Review, 67(2), 89-104.

6. Taylor, R.M., & Zhang, H. (2022). "Comparative Efficacy of Antiviral Treatments Against Tobacco Mosaic Virus in Field Conditions." Crop Protection Science, 44(6), 445-461.